Equipments

bottling plants

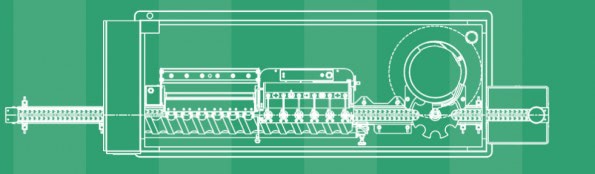

Garrafa - Engarrafamento Linear Automático - GAI

MLE 881 BIER - mle 881 hp

A versatile, compact solution featuring innovative technology with high quality filling for flat and effervescent products with maximum reduction of dissolved oxygen supply. Possibility of filling products sparkling at room temperature inducing energy saving and a better respect of the environment as well as the possibility of being able to label directly with adhesive without fear of condensation.

Linear rinser (electropneumatic for injecting a different amount of water depending on the size of the bottle with adjustment on the PLC).

Linear filling with electropneumatic nozzles to minimize the differences in the cadences compared to the various containers because all the nozzles work at the same time unlike conventional rotary turrets.

Filling quality is the same regardless of format, volume and cadence.

Once the product recipe is registered in the PLC, it is not influenced by the rate changes.

Reduction of dissolved oxygen inputs reduces sulphite inputs.

Possibility of several types of capping / capping on the same column. (Up to 3 different)

Speed of format changes optimized by the use of multi-format screws and stars, centralized level settings as well as electrical and height-adjusted settings for all columns.

Monobloc allows to work all types of bottles cylindrical or conical of 60 to 115 mm of diameter without changes of equipment.

Separate management of all circuits (vacuum, degassing, filling, leveling, gas compensation) ensures perfect and controlled sanitation.

Monobloc meeting the needs of a wide range of companies.